AEROSOLS → AUTOMATIC LINES → 120-200 CPM → FILLING AND CLOSING MODULES

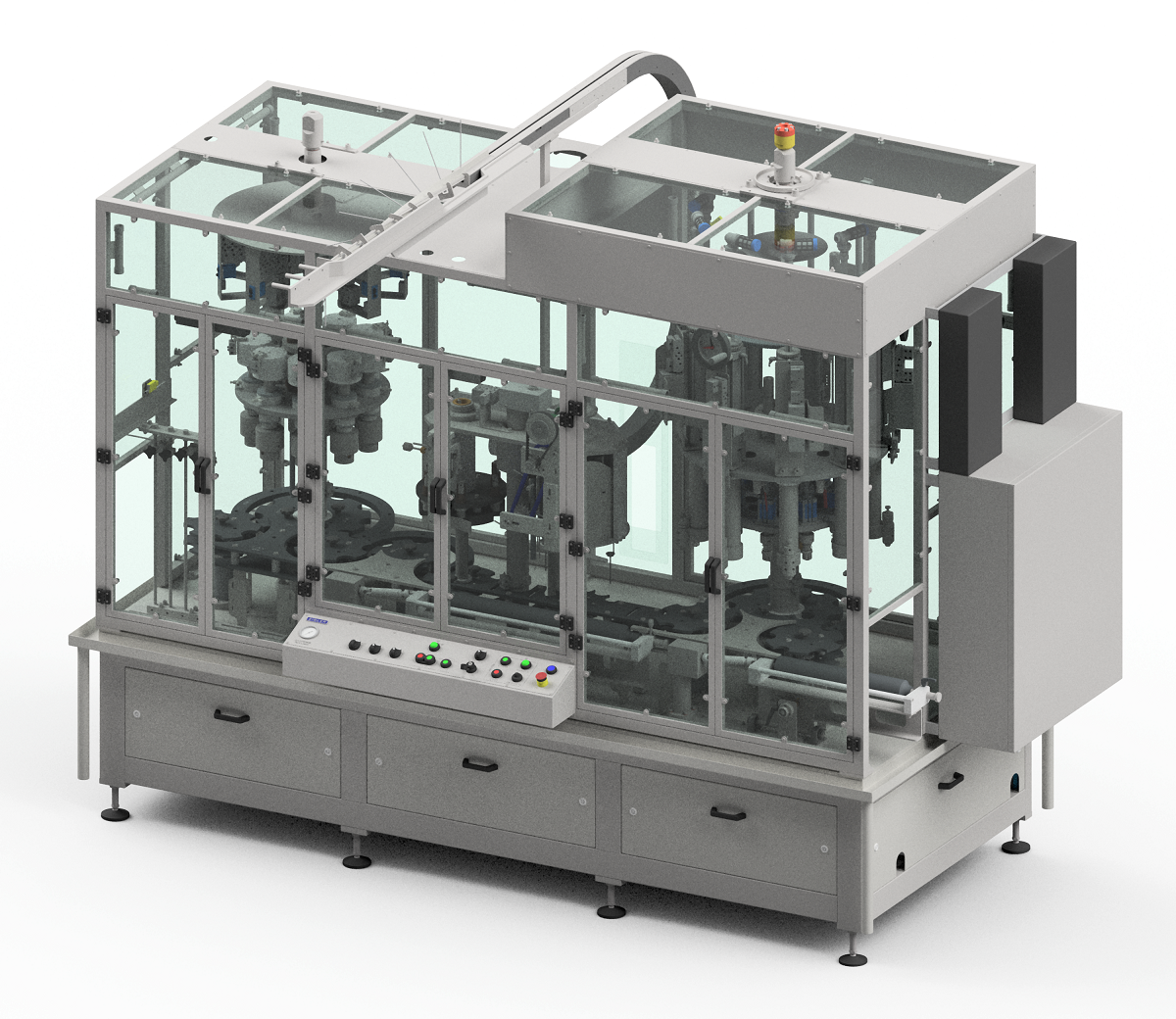

FILLING AND CLOSING ROTATIONAL MODULE ZIGMAT 180-3 TYPE Z-1432

The rated efficiency of the device is up to 180 pcs / minute. All working cycles take place during continuous (non-stop) rotary motion forced by the electric drive system.

Rotational Module Zigmat 180-3 is a device that is part of the automatic aerosol production line and is designed for the following stages of the production cycle:

- Picking up empty containers from the conveyor;

- Filling empty cans with liquid product- the action carried out by filling module equipped with 9 cylinders with working heads;

- Feeding the aerosol valve on the container and preparing it for the crimp.

- Crimping the valve on a filled can with the optional vacuum function. The task is performed using 9 crimping modules.

- Final product transport to a destination point.

Scroll down

Working parameters

Working parameters

Capacity:

up to 10800 pcs/h (180 pcs/minute)

Working pressure:

0,8 MPa (8 bar)

Containers height:

100 - 320 mm (using replaceable equipment)

Containers diameter:

ø35 – ø66 mm (using replaceable equipment)

Dimensions and weight

Width:

3440 mm

Length:

1840 mm

Height:

2750 mm

Weight:

~3600 kg

Supply parameters

Supply type:

Electric and pneumatic

Required supply pressure:

0,8 ÷ 1,0 MPa (8 ÷ 10 bar)

Air consumption:

63 m3 /h

Required supply voltage:

3x230 VAC 50 Hz

Power:

2.2 kW

Quality of compressed air:

IV-th class (according to ISO 8573-1) for temperatures 15 ÷ 35°C

Product supply pressure:

0.2÷ 0.6 MPa (2÷6 bar)