The amount of the dosed product is adjusted in the range of 5 ÷ 510 ml (for product cylinder ø50 mm) with tolerance up to ± 0.5 ml.

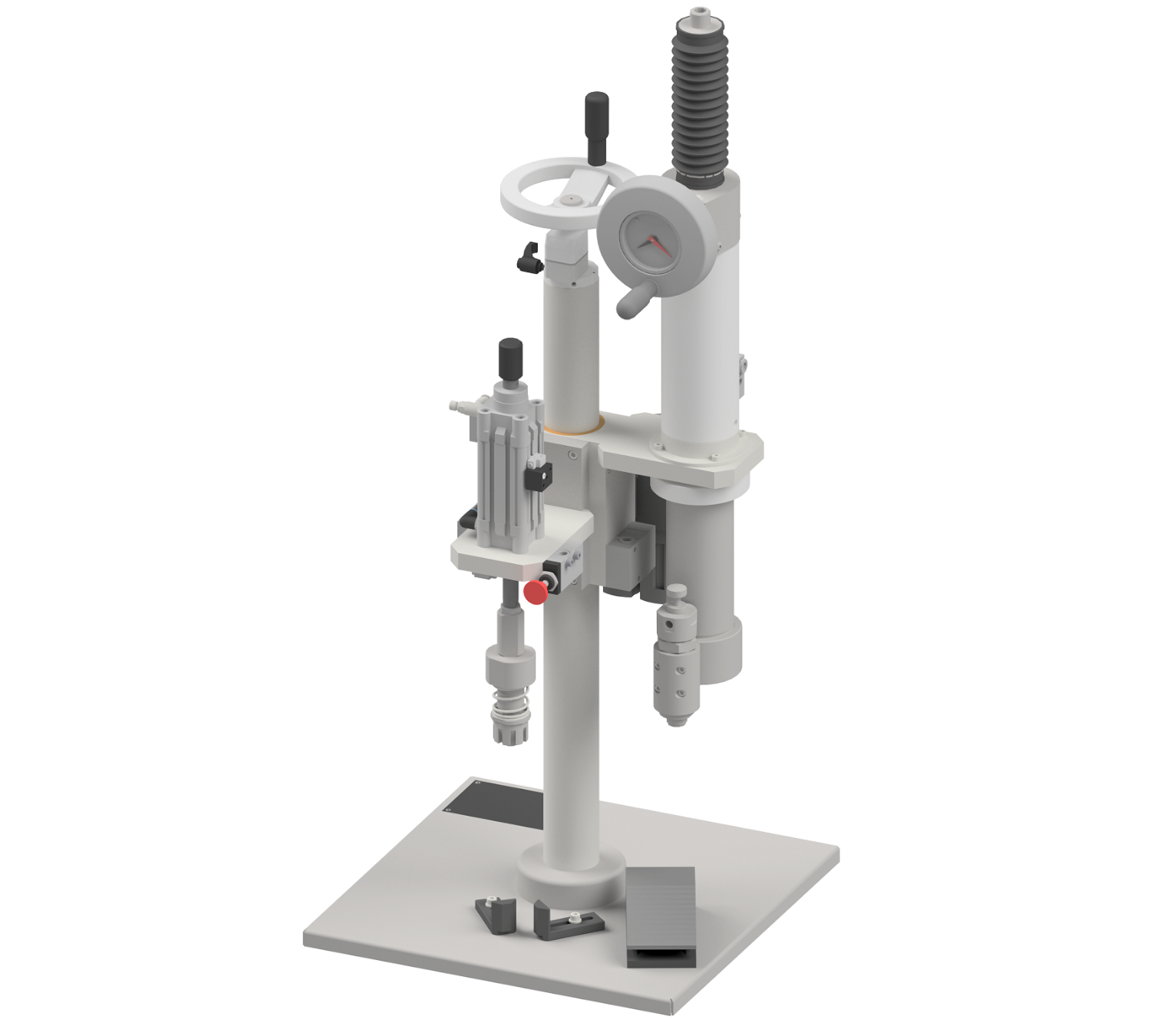

The machine may be placed in the processing line for filling aerosol cans as a semi-automatic on-table model with manual control by an operator or as a self-acting unit in an Automatic Rotation Module.

Where necessary, the machine can be provided in GMP suitable design with all steel elements that are in direct contact with product made from AISI 316L and all gaskets made from pharmacy/food approved materials.