The device can handle all types of 1” (25.4 mm) aerosol valves made from tinplate or aluminum sheet which are in compliance with EN 14848 (FEA 202 standard) and aerosol containers of diameters range ø35 – ø66 mm made from tinplate and aluminum sheet compliant with EN 14847 (FEA 201 standard), EN 15006, EN 15008 (FEA 220 standard), EN ISO 90-3 (FEA 101 standard), FEA 203 standard.

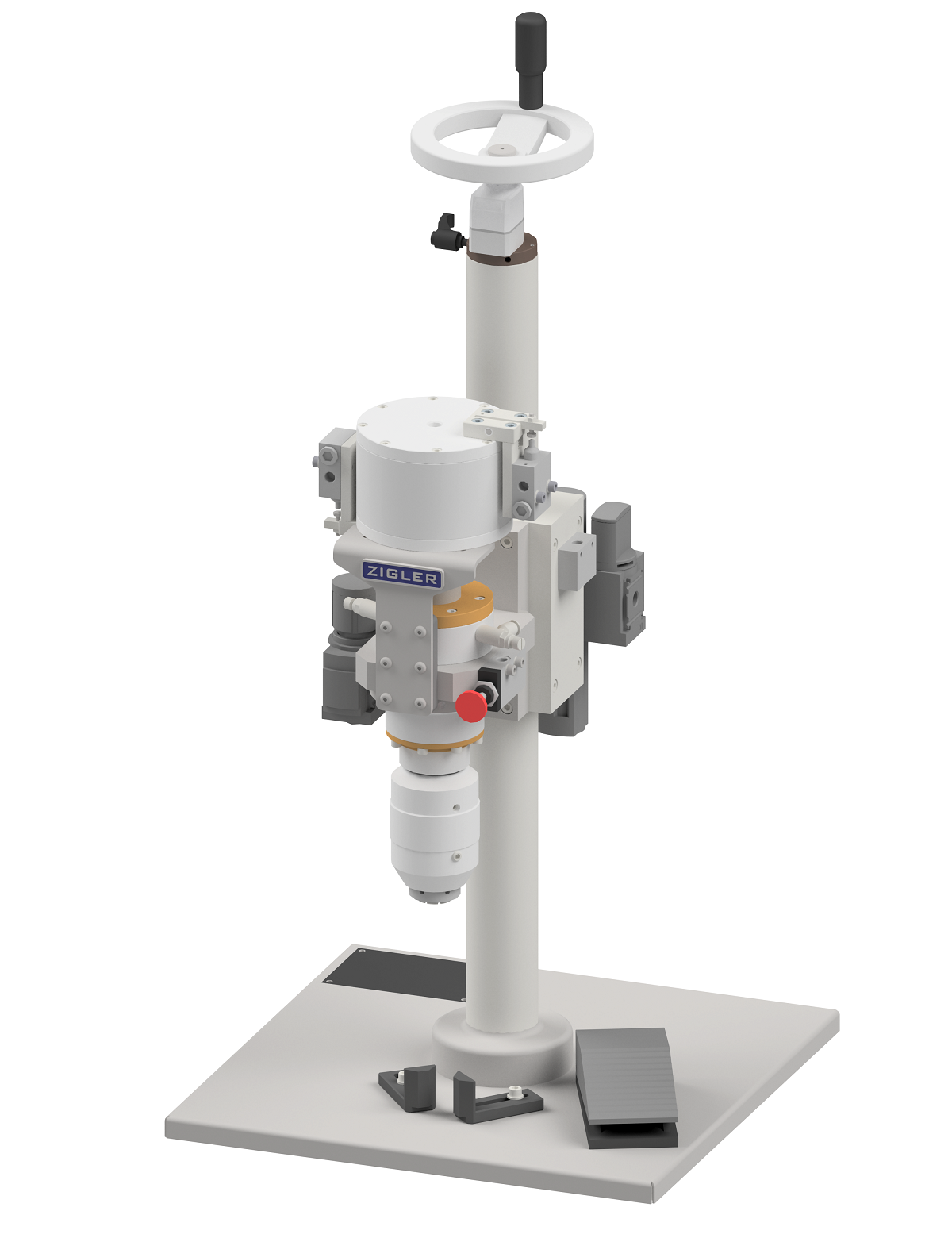

The machine may be placed in the processing line for filling aerosol cans as a semi-automatic on-table model with manual control or as a self-acting unit in an Automatic Rotary Module.