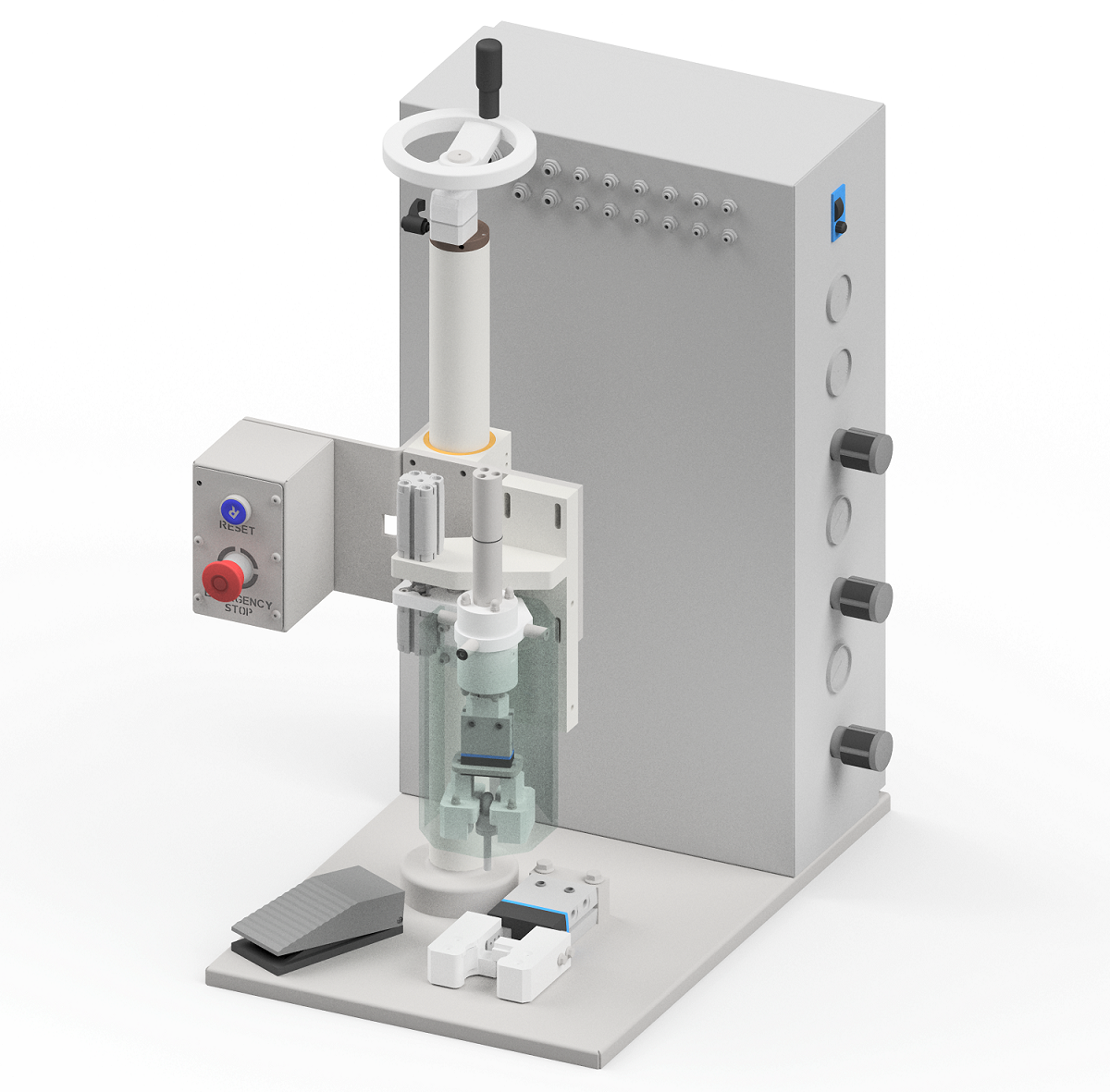

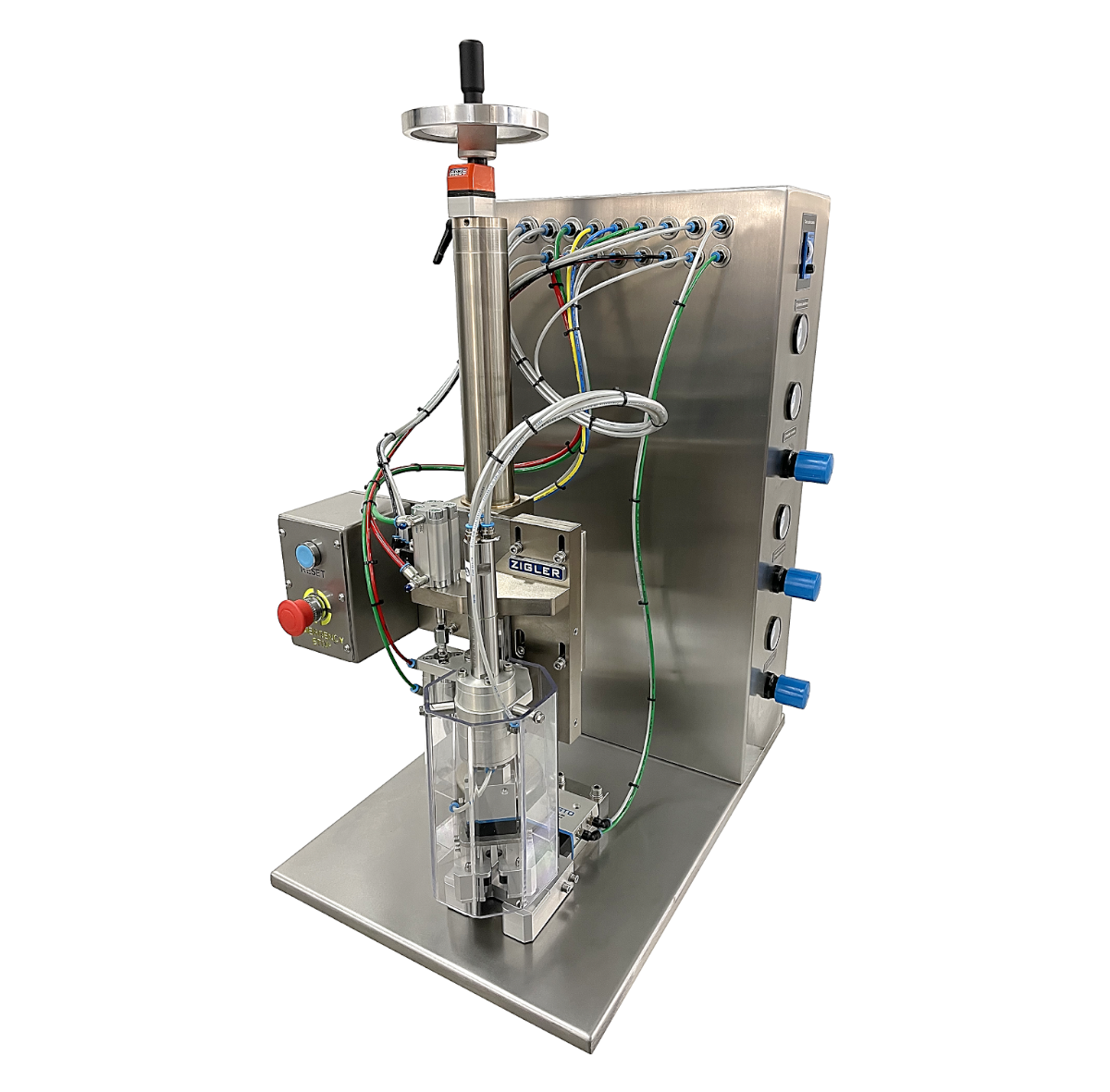

The bottle and screwcap are placed in the machine by hand. Using the exchangeable capping jaws and bottle jaws, it’s possible to work with bottles and caps up to 120 mm in diameter.

The working unit is mounted on the support stand equipped with a height adjustment mechanism, allowing the machine to handle bottles with caps with total height up to 300 mm.

The machine is operated with compressed air only. The pressure exerted on the bottle, the grip pressure, capping time and capping motor torque are fully adjustable.