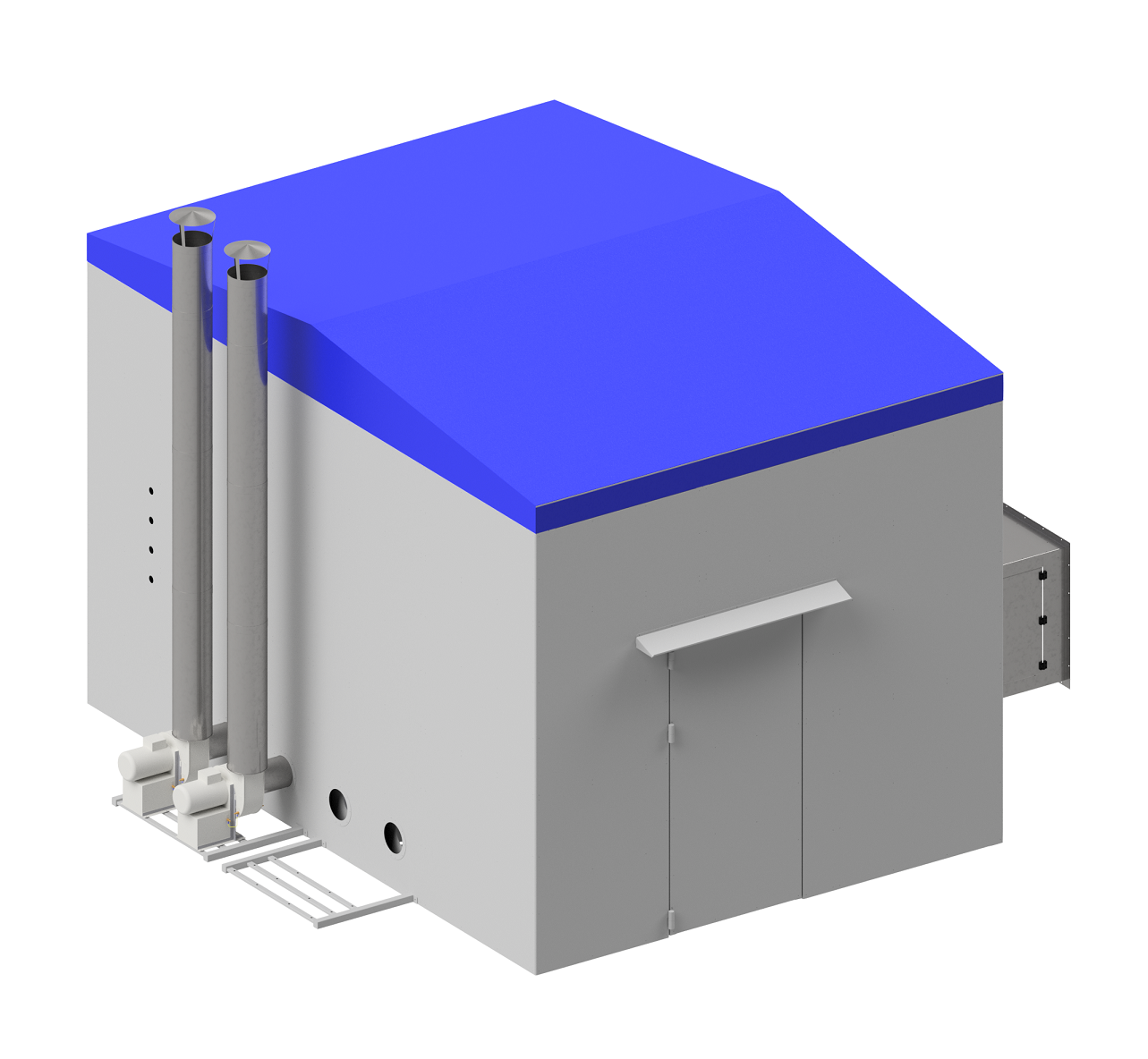

It has a very well-developed ventilation system that ensures multiple air changes in the container per minute, central heating with a heat exchanger that feeds warm air into the device, which effectively prevents the freezing of valves and outlet manifolds during gasification.

Cut off valves and gas sensors guarantee safety of operation. Multi-stage warning system and monitoring system enable prompt reaction to possible dangers. The entrance door is equipped with a protection against opening during operation of the unit. When activated, the protection stops operation of the complete line. Possible disturbance in the air exchange cycle are prevented in this way. The complete structure is encased with corrugated sheet metal while all ventilation channels are made of stainless steel.

The gas house has a light-weight roof structure made of plastic. Working cycle can be monitored by operators by means of a system with a camera in Ex enclosure and a monitor located in the production hall. All systems inside the container are integrated by a PLC-based production line control cabinet.