According to accepted standards, testing proceeds by bathing filled and closed aerosol containers in water at 55⁰C for about 3 minutes.

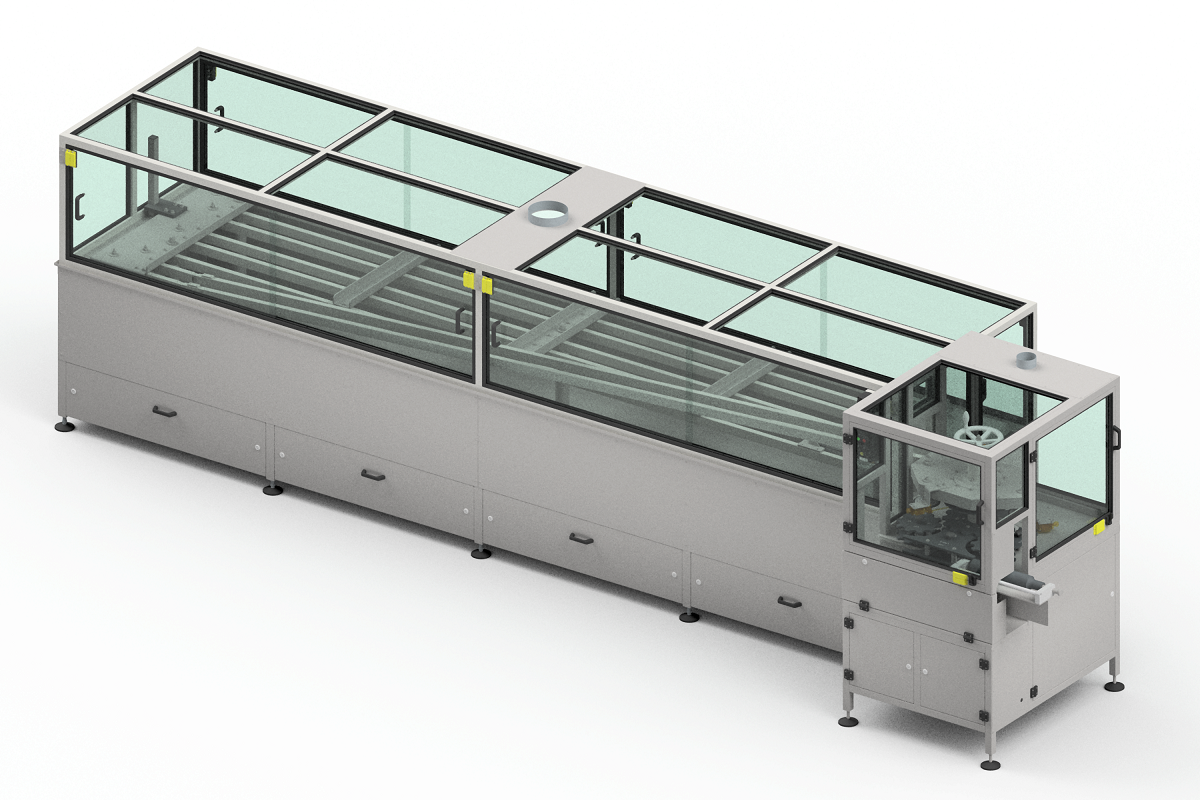

Containers are being transported through a tank filled with hot water by means of driving wheel and a chain with clips for holding the attached containers. Speed of attaching/detaching is smoothly regulated and allows to adapt Test Bath to the capacity of entire line.

Total capacity (assuming that bath will last 3 min) comes to about 120 containers per minute. Test Bath has been also equipped with pneumatic drying system for containers.

Main tasks of the device: