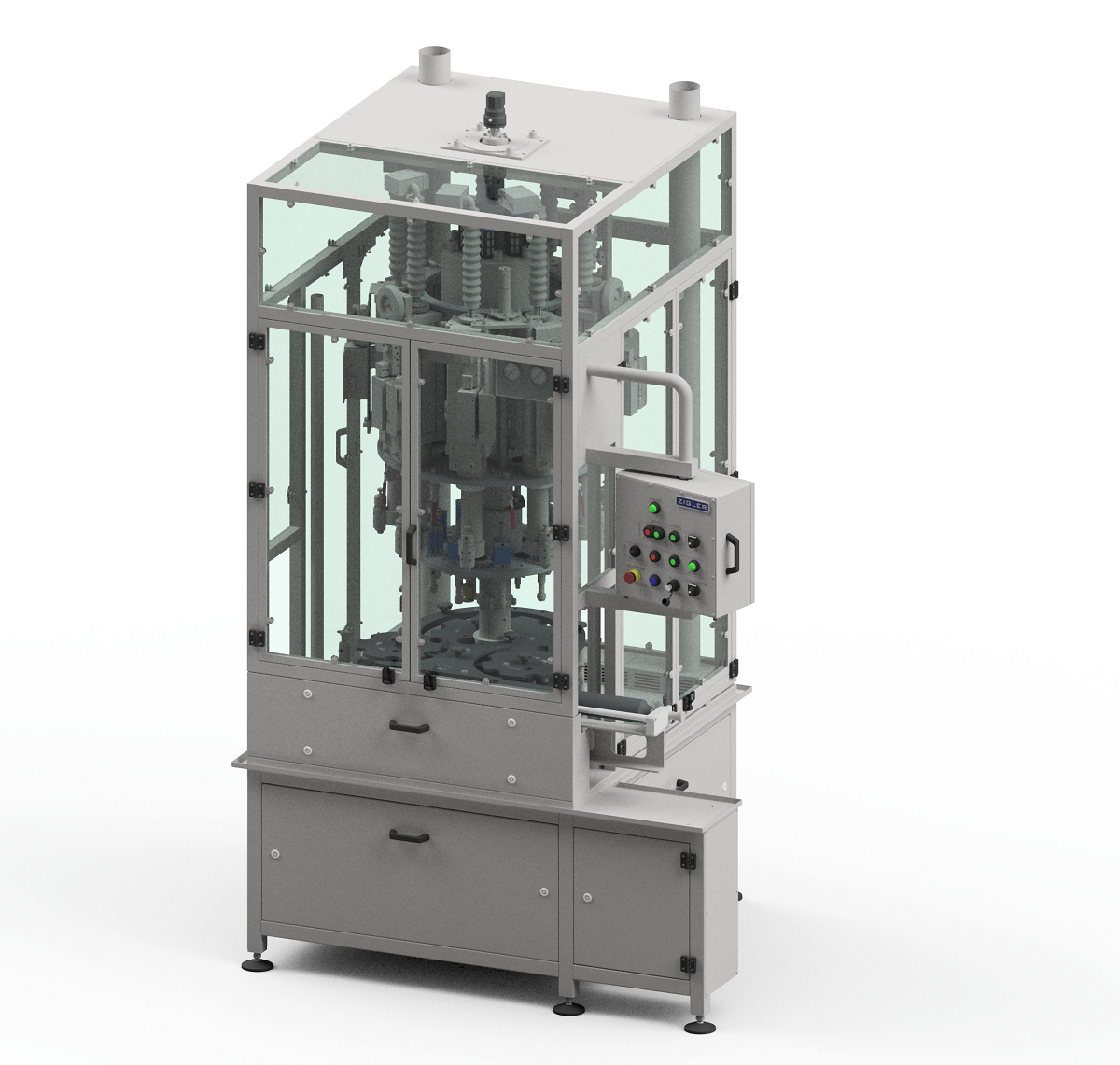

Rotational Gasifying Module ZIGMAT 180-1 is part of a production line and is intended for filling aerosol containers with a propellant through a crimped aerosol valve. The task is performed using 9 gasifying modules.

The rated efficiency of the device is up to 180 pcs / minute. All working cycles take place during continuous (non-stop) rotary motion forced by the electric drive system.