Bottles are provided manually.

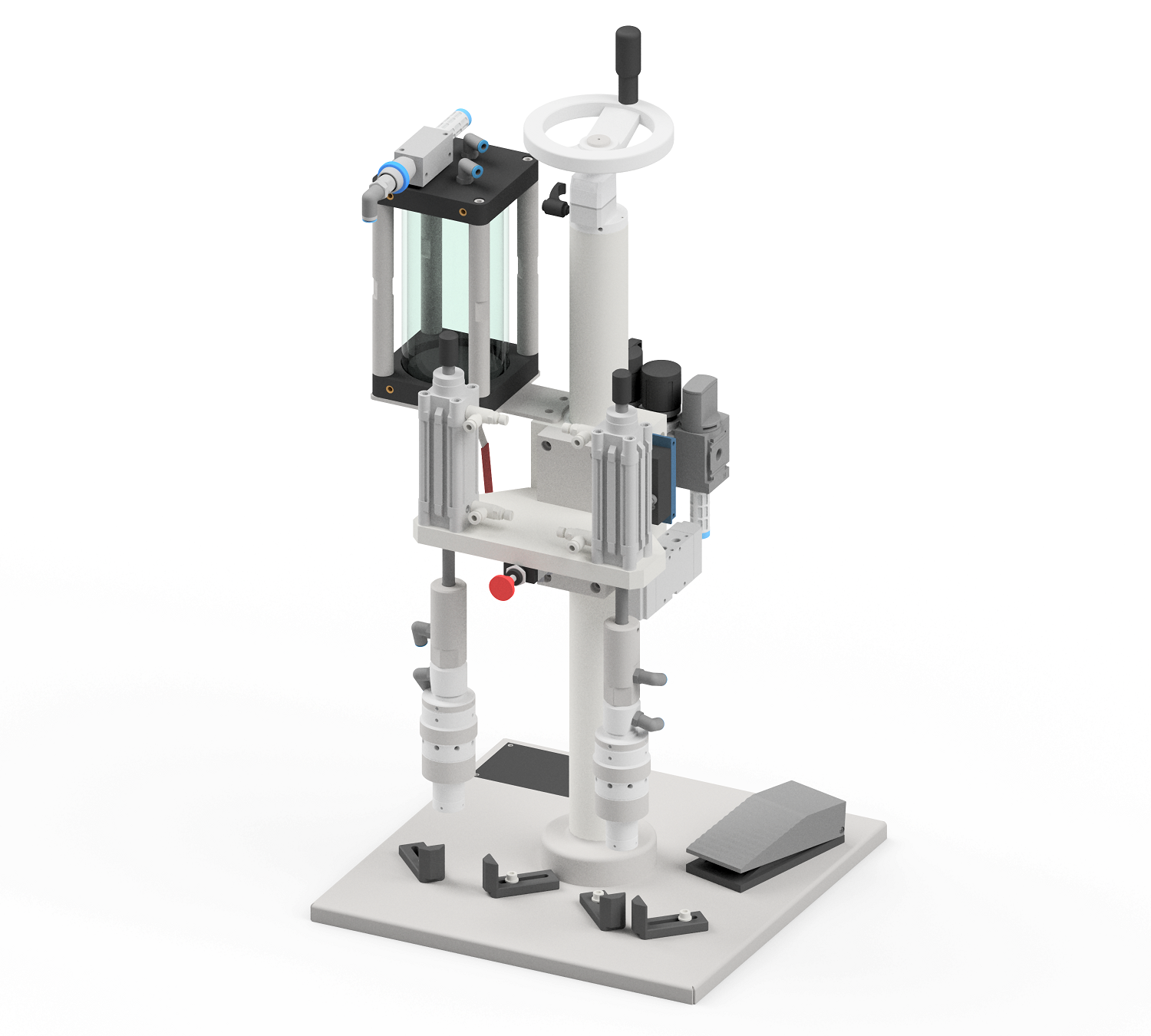

The use of vacuum mechanism allows to maintain equal level of liquid in each bottle, regardless of volume differences (even very small – being a result of glass thickness differences).

Device is equipped with its own vacuum generator and with drain tank, where excess of liquid is stored during liquid leveling in bottles.