Materials of the highest quality (stainless or acid resistant steel) are used for the MRI construction, thus creating working conditions even in a highly hazardous environment. MRI machine is designed to prevent a hazard of explosion during production process.

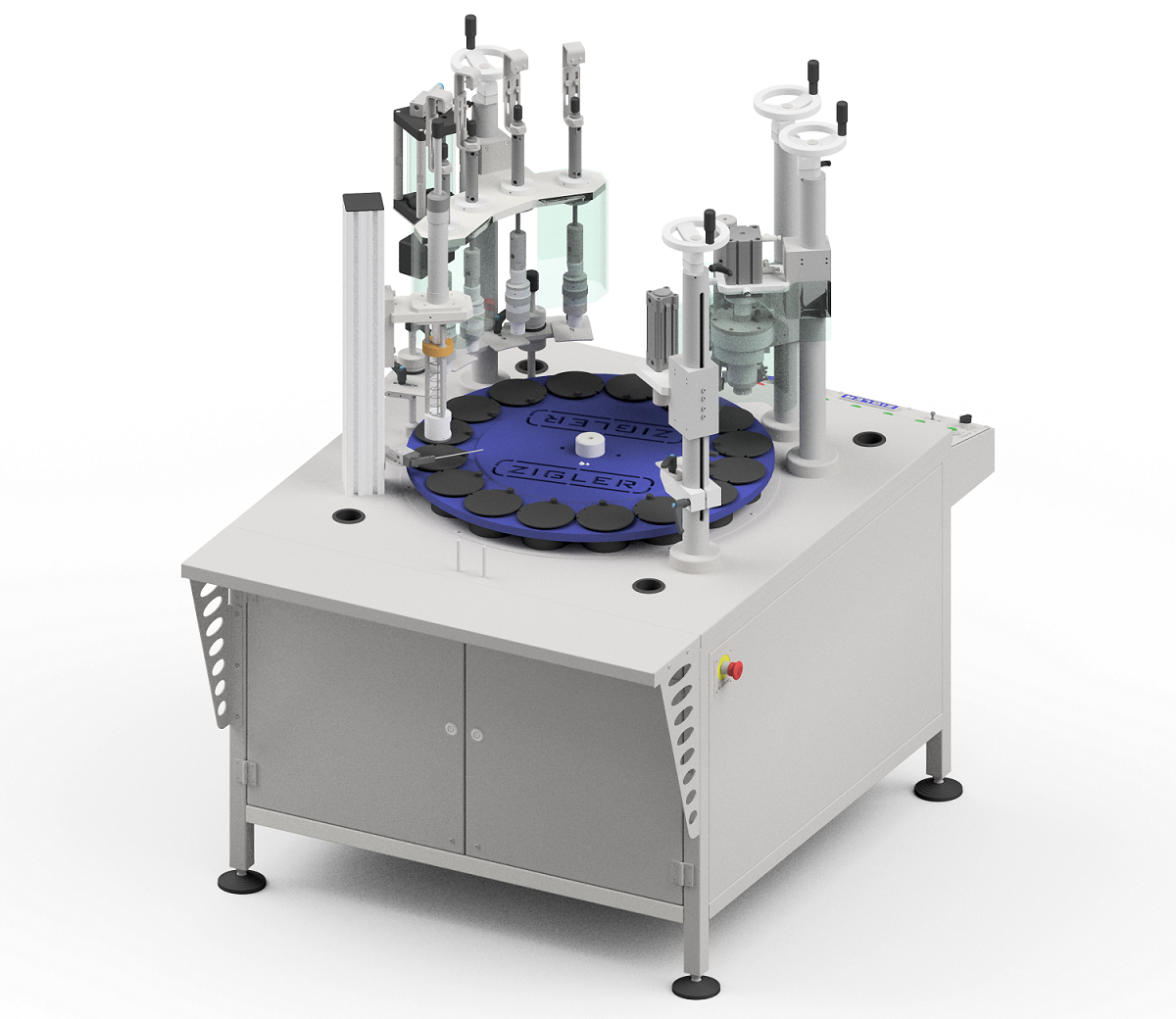

Exchangeable indexing wheel sockets, easy and smooth regulation of modules height: filling and crimping, allow changing of production profile efficiently and, owing to this, the adaptation to quickly changing market demands does not create any problem.

As part of the standard equipment, bundled with the machine, the User receives 1 set of format inserts, which (depending on the geometry of the bottles) allow working with 1 or 2 types of bottles.