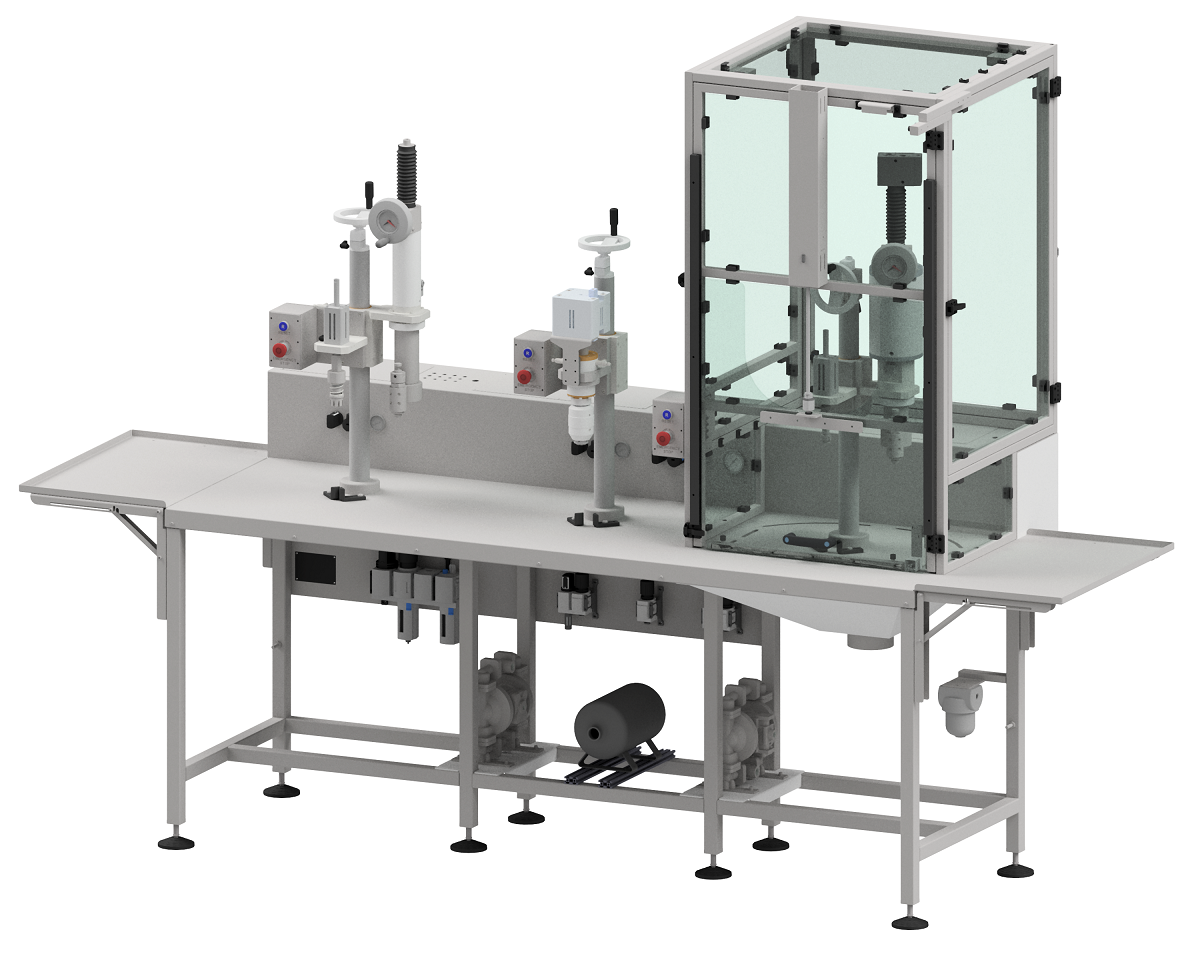

AEROSOLS

LABORATORY AEROSOL FILLING SYSTEM TYPE Z-2068

System equipment:

- Stainless steel table with an integrated pneumatic control for all working modules;

- Product filling module;

- Aerosol valves crimping module;

- Gas filling module;

- Product pump;

- Gas (propellant) pump;

- Built-in propellant filter (40 µm);

- Connection lead for the product;

- Connection lead for gas;

- Aerosol valve crimp controlling device;

- Aerosol can pressure controlling device;

- Laboratory glass probe.

Working parameters

Operational parameters

Production capacity:

420 ÷ 1800 pcs/h (7 ÷ 30 pcs/min). Effective capacity depends on product and propellant doses, aerosol valves type, production organization and operator’s experience. Standard assumption is: 1800 pcs/h (30 pcs/min) for 100 ml dose; 900 pcs/h (15 pcs/min) for 200 ml dose; 420 pcs/h (7 pcs/min) for 500 ml dose;

Range of dosage:

Depending on order (up to 510 ml)

Dosing tolerance:

± 0.5 ml for 100 ml dose; ± 0.7 ml for 200 ml dose; ± 1.0 ml for 500 ml dose;

Crimping type:

Standard or vacuum (additional option)

Dimensions and weight

Width:

Max 3070 mm

Length:

1080 mm

Height:

2330 mm (+/- 50 mm of adjustment)

Mass:

550 kg

Supply

Supply type:

Pneumatic

Air supply pressure:

8 ÷ 10 bar (0,8 ÷ 1,0 MPa)

Air consumption (for capacity 500 pcs/h):

6.6 m3/h - for 20% of max product and gas dosage; 10.4 m3/h - for 50% of max product and gas dosage; 21 m3/h - for 100% of max product and gas dosage;

Compressed air quality:

CLASS IV according to ISO 8573-1 for 15 ÷ 35°C