AEROSOLS → AUTOMATIC LINES → up to 60 CPM → FILLING AND CLOSING MODULES

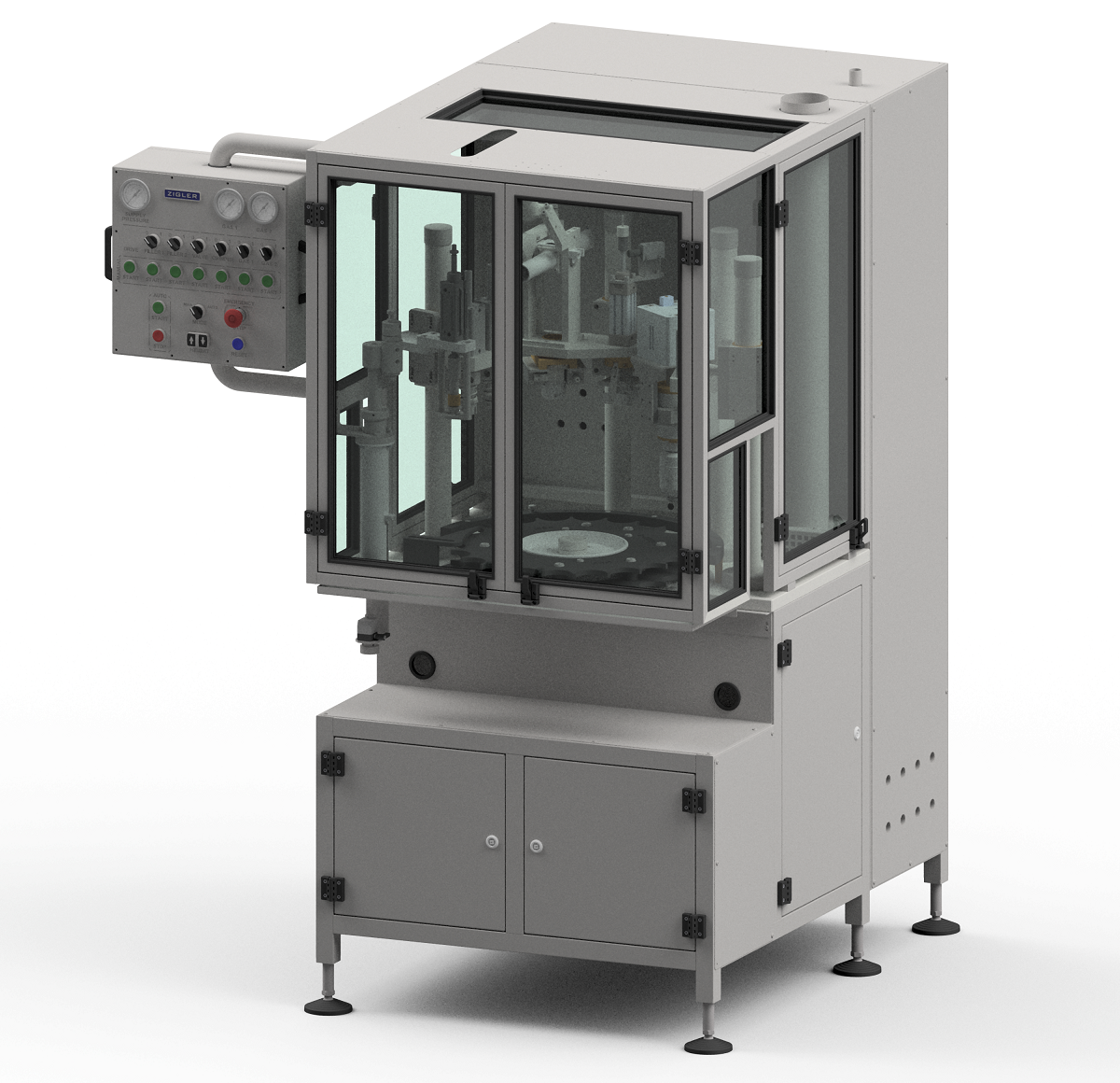

FILLING AND CLOSING AUTOMATIC INDEXING MODULE TYPE Z-1059

Filling and Closing Automatic Indexing Module Z-1059 is part of automatic aerosol production line and is intended for the completion of the following production phases:

- Collecting empty cans with valves from conveyor;

- Filling aerosol cans with liquid product - performed using 1 or 2 filling modules with maximum dose up to 510 ml each (depending on order).

- Inserting valves into aerosol cans - performed by a valve inserter with an valve presence check module.

- Crimping the inserted aerosol valves (with optional vacuum).

- Gasifying aerosol cans - performed using 1 or 2 gasifying modules with maximum dose up to 510 ml each (depending on order).

- Placing finished product back on conveyor belt.

Scroll down

Working parameters

Working parameters

Capacity:

1000 ÷ 3600 pcs/h (16 ÷ 60 pcs/min) – depending on propellant and product dose or valve type

Product dose:

Up to 510 ml for each module

Gas dose:

Up to 510 ml for each module

Containers diameter:

ø35 mm ÷ ø66 mm

Containers height:

65 mm ÷ 320 mm

Dimensions and weight

Width:

1450 mm

Length:

1320 mm

Height:

1840 mm

Weight:

~665 kg

Power supply

Supply type:

Pneumatic

Required supply pressure:

0.8 ÷ 1.0 MPa (8 ÷ 10 bar)

Compressed air quality:

Class IV according to ISO 8573-1 standard for temp. 15 ÷ 35°C

Connection:

External thread G¾”

Liquid product connection

Supply pressure:

0.3 - 1 MPa (3 - 10 bar) – depending on the product density and viscosity

Connection size:

External thread G ½” to each filling module

Propellant connection

Supply pressure:

5 bar above propellant vapour pressure

Product connection:

G½” external BSPP thread with 60° cone to each gasifying module