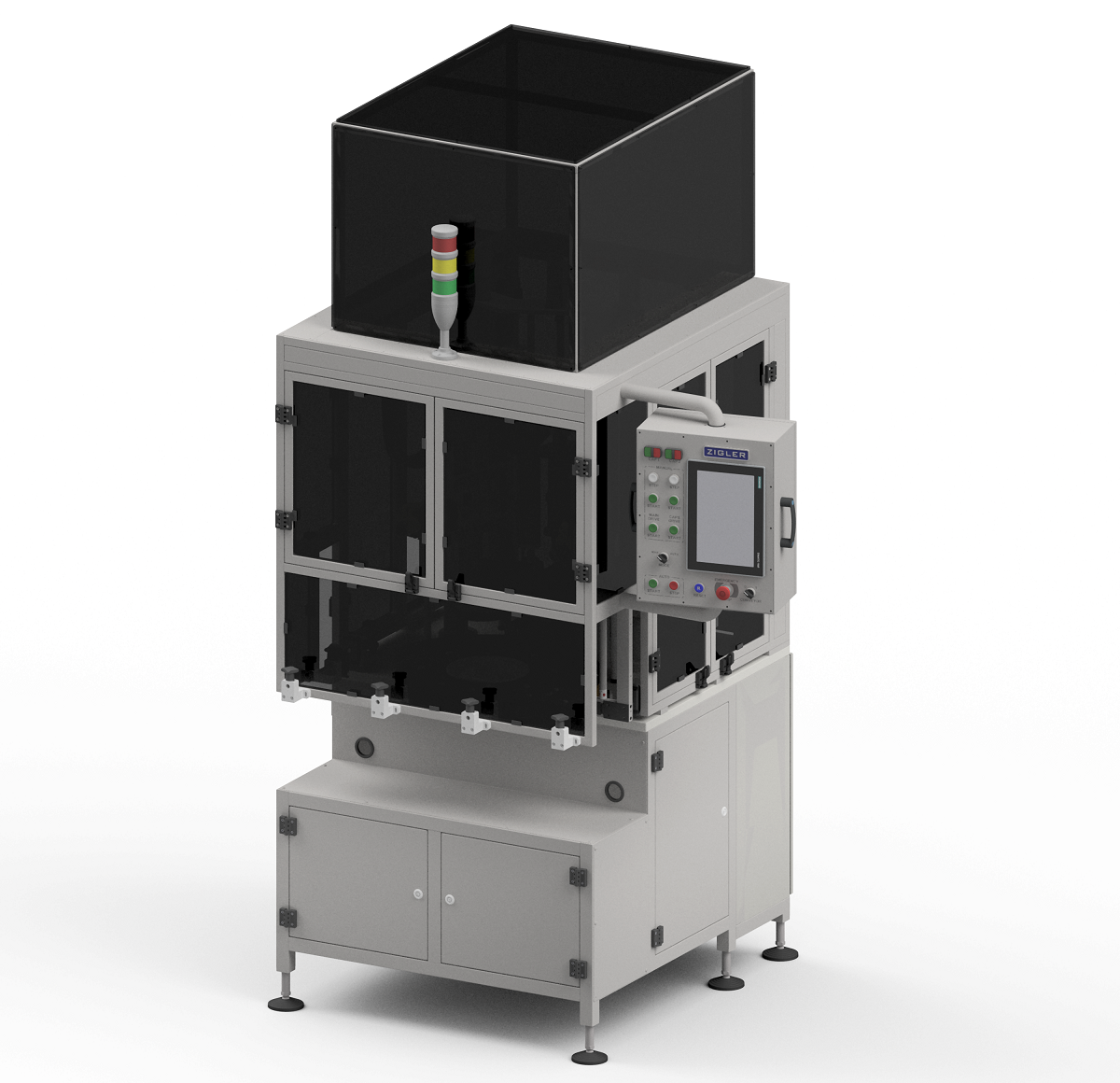

The vision system based on Omron components (sensor, lens and illuminator) is designed to detect the position of the cap relative to the marker on the container, which enables the determination of the rotation angle set for the head equipped with a vacuum gripper holding the caps.

The movement of the gripper tip is realised by LinMot magnetic linear-rotary actuators. The machine is equipped with Mitsubishi servo drive, indexing the containers with a double step, so in one cycle there is the orientation and seating of 2 caps simultaneously – all systems are doubled (vision system, vacuum gripper, magnetic drives). The rotation of the head in each gripper is realized by JVL servo drives. The whole system is controlled by a dedicated S7 series PLC from Siemens. Simatic HMI panel equipped with a 12″ touch screen is responsible for communication with the operator.

Due to the full automation of the entire cycle, all settings are only programmable from the touch interface. The use of Asem router, allows for comprehensive remote diagnostics using Ethernet or 3G/4G interface.

Main functions of the device: